The challenge: Limited visibility into production performance

In today’s highly competitive manufacturing environment, every production manager faces the same pressing question: “How efficiently are our production lines running?”

For Vietnam’s leading air-conditioner manufacturer, this question became even more critical as the company scaled output toward one million units per year at a USD 72-million facility. Despite the rapid expansion, managers still struggled with limited visibility into output performance, machine health, manpower allocation, and overall line efficiency.

This lack of real-time insights meant that detecting production issues could take hours—or even days. By the time a problem surfaced, the delay had already caused inefficiencies, lost output, and missed opportunities for improvement. The need for a centralized, real-time production monitoring solution became urgent.

The solution: An IoT-enabled production monitoring system

To bridge the gap between factory-floor operations and management decision-making, GITS developed a comprehensive, IoT-enabled Production Monitoring System designed for accuracy, speed, and scalability.

The first part of the solution focused on real-time data collection and analytics. GITS built a service application capable of integrating directly with the factory’s existing systems and equipment. This eliminated the need for manual data gathering and time-consuming reporting. Managers gained immediate access to all key production metrics, allowing them to understand what was happening on the shop floor at any moment.

The second part of the solution was a web-based monitoring dashboard. Designed with an intuitive interface, the dashboard visualises live production data through clear charts and analytics. This helps management teams make data-driven decisions and address issues proactively rather than reacting at the end of a shift.

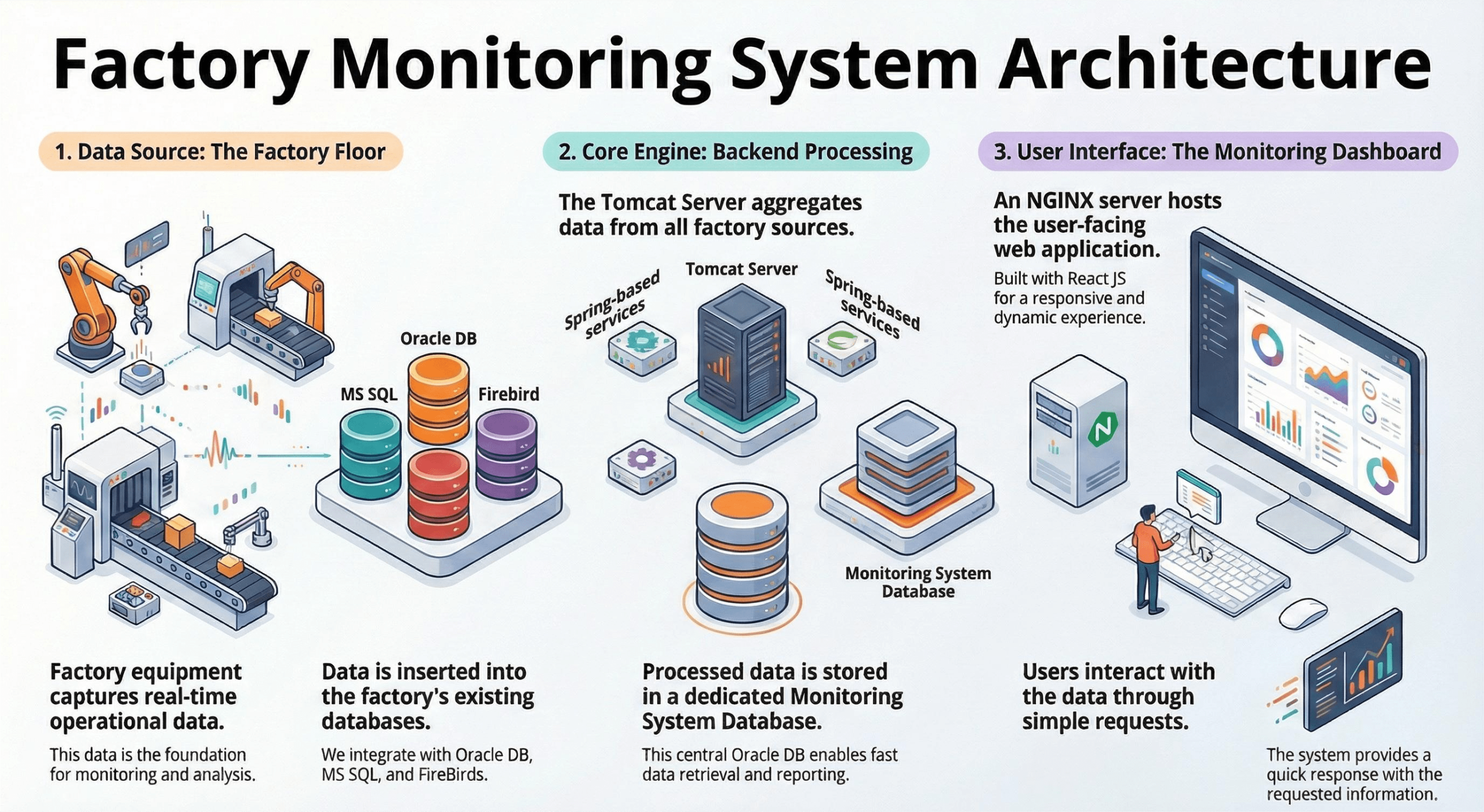

The architecture: Reliable, scalable, and built for 24/7 operations

The system’s architecture was engineered to withstand the demands of a high-volume manufacturing facility. The frontend was developed using ReactJS to ensure smooth, real-time dashboard updates. On the backend, Java Spring Boot handled scalable data processing. The system integrates seamlessly with Oracle DB, MySQL, and Firebase for accurate data collection, while NGINX and Tomcat provide stability in deployment. This architecture ensures the system can run continuously, delivering the reliability expected in modern production environments.

Real results: Turning production data into action

Once the new monitoring system was deployed, the manufacturer gained complete oversight of every production line. Issues were identified within minutes instead of hours, allowing teams to take immediate corrective actions. Defect tracking also became more transparent, enabling long-term quality improvement initiatives. Instead of discovering problems at the end of the shift, managers received real-time alerts the moment a metric deviated from its target. This shift fundamentally transformed how decisions were made, significantly reducing downtime and improving overall productivity.

Our approach: A full-cycle development partnership

GITS supported the project from start to finish. The team handled IA/SRS documentation, system architecture, database design, development, testing, deployment, and ongoing optimization. The project has been running from April 2025 to the present, supported by a dedicated team of five members working under an AGILE/SCRUM methodology. This approach ensured continuous improvement and flexibility throughout the entire development cycle.

Is your factory ready for real-time production monitoring?

Many factories discover production problems long after they occur simply because they lack the right visibility tools. If your operations still rely on manual data collection or if bottlenecks are difficult to identify in real time, an automated monitoring system may be the key to unlocking higher efficiency. As manufacturers scale, having accurate and instant production insights becomes essential—not optional.

Let’s build your production monitoring solution

If your organisation is ready to elevate production performance, GITS is here to help. We specialise in building custom manufacturing systems that integrate smoothly with your existing infrastructure. Our experts will evaluate your current production processes, design a tailored architecture, implement the system with minimal disruption, and provide continuous optimisation.

If you want a Production Monitoring System, you can request a free consultation with GITS’s Tech Expert team. Share your current manufacturing setup, and we’ll show you how GITS would structure the solution so you can decide if we are the right technology partner for your next project.