導入

今日の競争が激化する製造業界において、効率性と精度は企業の成功を左右する重要な要素です。

日本のある大手重工業メーカーは、受注管理から原価見積に至るまで、製品ライフサイクル全体の管理に課題を抱えていました。

こうした課題を解決するため、GITSは ARAS Innovator、AWS、Node.js、React.js、Flutter を活用し、カスタムPLM(製品ライフサイクル管理)システムを開発しました。

本ケーススタディでは、GITSが構築したスマートで拡張性が高く、コスト効率に優れたPLMシステムが、業務効率の向上、手作業の削減、データセキュリティ強化にどのように貢献したかをご紹介します。

課題:成長を阻害するレガシーシステム

本プロジェクトの顧客は、造船、重機、橋梁建設、航空エンジン製造を手がける重工業メーカーです。

製品ライフサイクル管理を最適化するため、柔軟でモダンなPLMシステムが求められていました。

主な課題は以下の通りです。

– レガシーシステムによる非効率性

手作業が多く、業務スピードと正確性が低下

– 拡張性の不足

将来的な事業拡大や業務変更に対応できない

– 予算制約

フルスクラッチでの再構築は現実的ではない

– データセキュリティへの懸念

大量データ処理に伴う高度なセキュリティとコンプライアンス要件

GITSは、これらの課題を解決し、製造業務を将来にわたって支えるコスト効率の高いカスタムソリューションを提供しました。

解決策:ARAS Innovatorを活用したカスタマイズPLMシステム

ARAS Innovator

GITSは、高い柔軟性と拡張性を持つ業界標準のPLMソフトウェア ARAS Innovator を基盤に、顧客要件に最適化されたPLMシステムを構築しました。

1. 受注・見積管理の一元化

受注プロセスをデジタル化し、顧客要望の管理、注文状況の追跡、原価見積の自動化を実現。業務効率を大幅に向上させました。

2. BOM(部品表)管理の自動化

生産工程全体で部品の作成・変更・追跡が可能なBOM管理機能を実装。

ヒューマンエラーを削減し、高い透明性を確保しました。

3. ワークフロー自動化とカスタムアドオン

GITSのエンジニアは顧客と密に連携し、ARAS Innovatorをカスタマイズ。

業務フローの自動化と、現場で使いやすいUIを実現しました。

4. セキュアなクラウドアーキテクチャ

AWSクラウド基盤を採用し、Node.jsとReact.jsによる高性能かつ拡張性の高いバックエンドを構築。

大量データ処理とセキュリティを両立しました。

5. モバイル対応によるリアルタイム管理

Flutterを用いたモバイルアプリを開発し、管理者や経営層が場所を問わずリアルタイムで状況を把握できる環境を整えました。

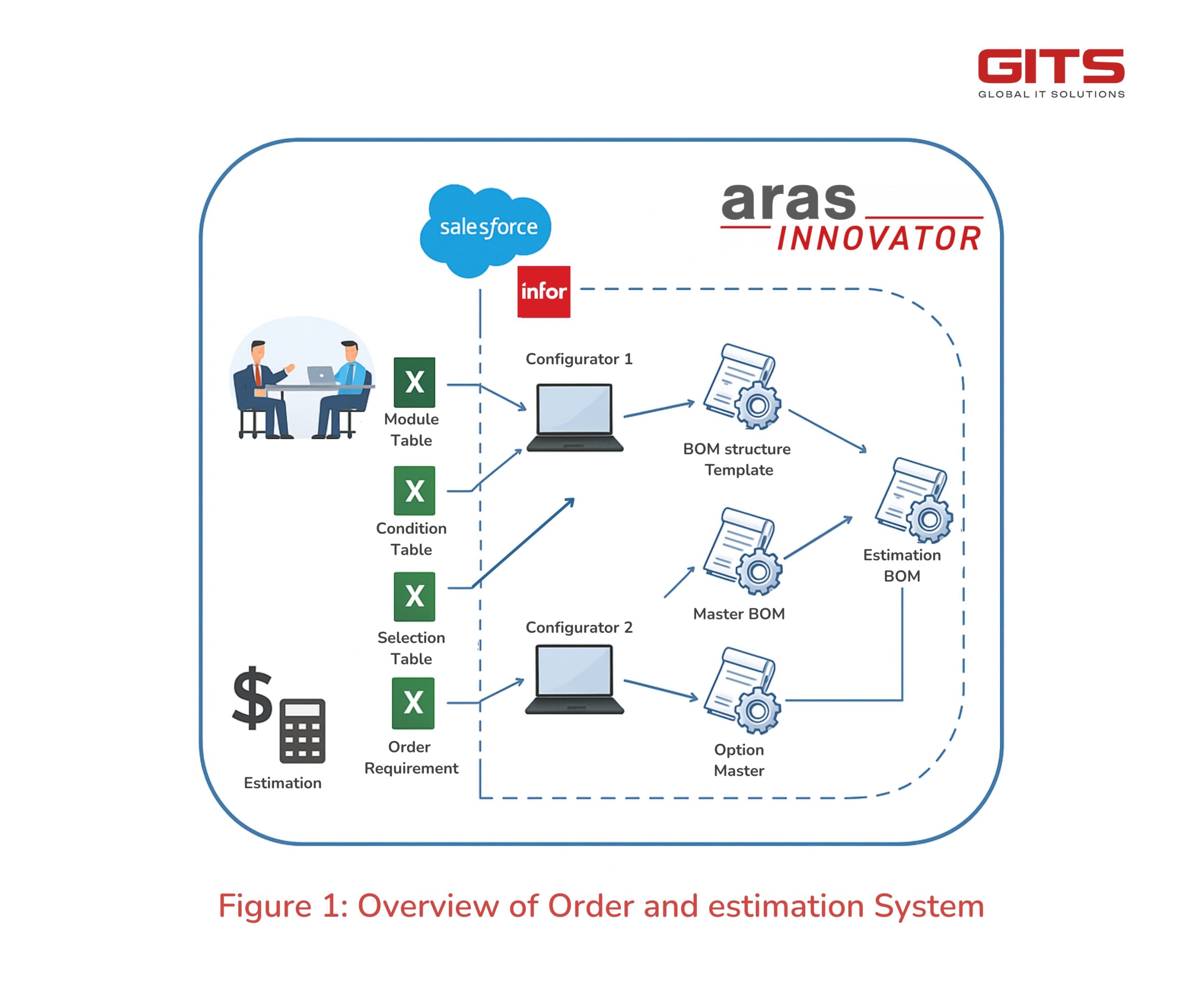

仕組み:システムアーキテクチャ

GITSのPLMシステムは、以下の要素を統合し、自動化されたデータドリブンな製造ワークフローを実現しています。

– Salesforce連携:受注入力・進捗管理の自動化

– Excelベースのコンフィギュレーター:柔軟な構成管理と意思決定支援

– BOM構造テンプレート:資材計画の精度向上

– 見積・原価計算機能:収益性を高める価格戦略を支援

– AWSクラウド基盤:高い拡張性とデータセキュリティモバイルアプリ:リアルタイム監視と情報更新

衝撃:効率化・コスト削減・持続的成長

GITS PLMシステム導入後、顧客は以下の成果を達成しました。

– 手作業を50%削減

ワークフロー自動化によりエラーを削減し、生産性を向上

– 受注処理時間を30%短縮

デジタル化により業務スピードを大幅改善

– 高い拡張性を確保

将来的な事業拡大やカスタマイズにも柔軟に対応

– セキュリティ・コンプライアンス強化

AWSによる安全なデータ管理を実現

– コスト効率の向上

資材管理と価格戦略の最適化により運用コストを削減

ソリューションの背後にあるテクノロジー

本システムは、以下の最新技術を活用して構築されました。

– ARAS Innovator:柔軟性と拡張性に優れたPLMプラットフォーム

– AWS(Amazon Web Services):安全なクラウドインフラ

– Node.js:高速なバックエンド処理

– React.js:直感的でレスポンシブなWeb UI

– Flutter:クロスプラットフォーム対応のモバイルアプリ開発

結論

GITSは、クラウドベースかつ自動化されたカスタムPLMシステムを通じて、顧客のコスト削減、業務効率向上、製品ライフサイクル管理の最適化を実現しました。

拡張性が高く、コスト効率に優れたPLMソリューションで製造業務を変革したいとお考えですか?

GITSは、製造業に特化したオーダーメイドのITソリューションを提供しています。