In today’s fast-moving logistics world, the warehouse is truly the heart of every business. Yet many companies still rely on manual warehouse management processes—using spreadsheets and depending heavily on human labor. This outdated approach leads to frequent issues: order confusion, inventory discrepancies, and the lack of real-time data for decision-making. Forward-thinking businesses have already adopted WMS to automate every aspect of warehouse operations—from inbound and outbound processes to real-time inventory tracking. More than just software, a modern WMS has become the backbone of efficient logistics, helping businesses cut labor costs, reduce errors, and significantly increase order fulfillment speed.

What makes WMS a game-changer within just months?

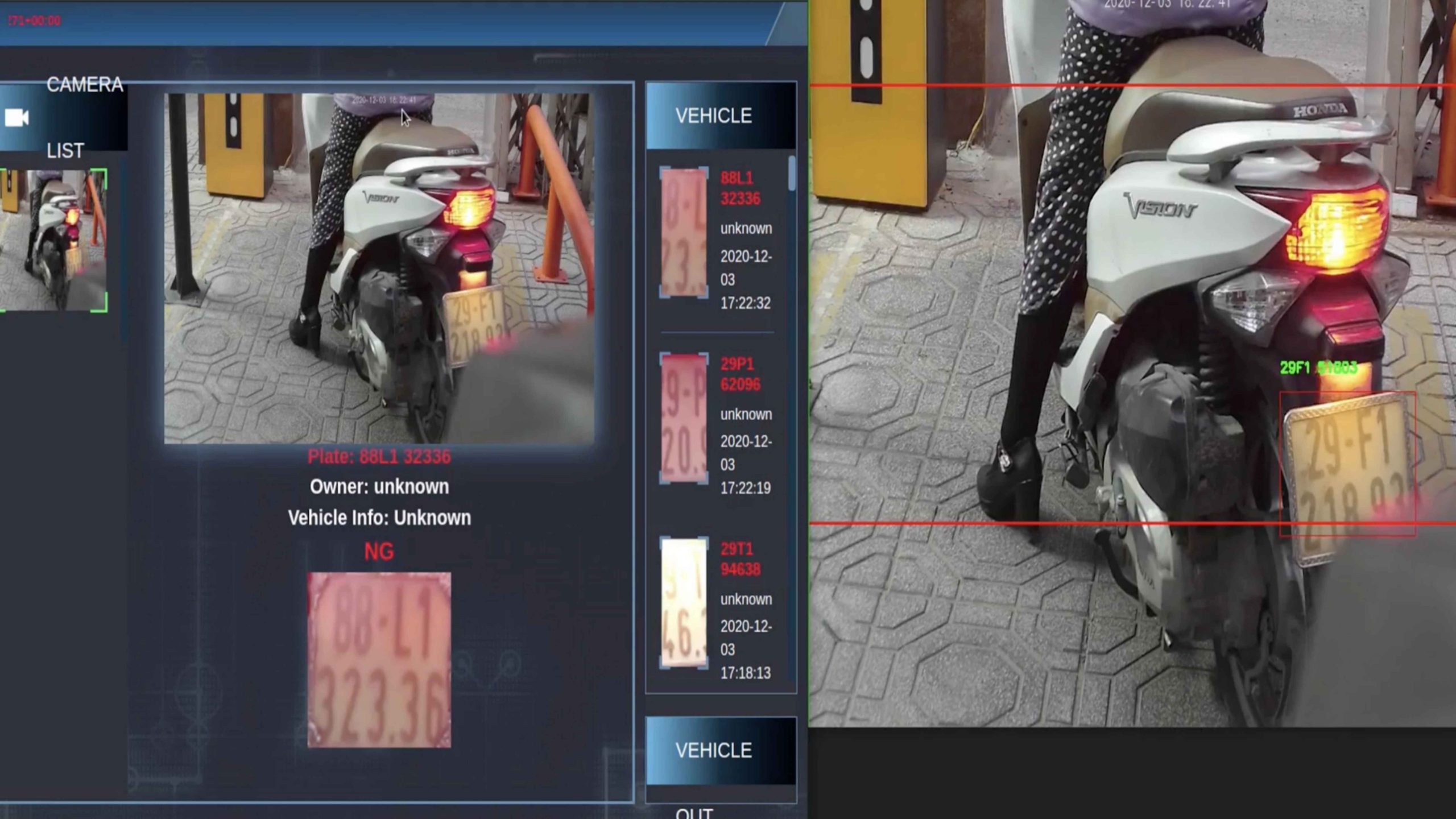

Real-time inventory control – down to the second

No more waiting for monthly stock takes. With a WMS, businesses can instantly know how much stock they have, where it is, whether it’s expired, and who last handled it. Instead of searching blindly among hundreds of SKUs, WMS provides real-time tracking for every item, updated automatically with each action. This allows companies to take control in any situation, whether it’s fulfilling a sudden large order or responding to delivery complaints.

Accelerate order processing without adding staff

When every warehouse task is systemized—from suggesting the shortest pick routes to optimizing packing locations and managing outbound schedules—order processing speed increases dramatically. In many cases, businesses can double warehouse productivity without hiring more workers. A well-designed WMS also reduces onboarding time for new staff thanks to its user-friendly interface and standardized workflows.

Minimize errors, maximize accuracy

Warehouse mistakes aren’t just human errors—they’re business losses: returns, reimbursements, lost customers. With WMS, the system automatically detects and alerts users of incorrect actions like wrong barcode scans, inaccurate quantities, or picking from the wrong location. Only authorized personnel can edit data, ensuring transparency and data accuracy across the warehouse.

Manage multiple warehouses from a single dashboard

As businesses expand—adding regional warehouses or fulfillment hubs—centralized visibility becomes essential. A powerful WMS enables managers to monitor operations across all warehouses in real time, analyze performance, and flexibly reallocate inventory between locations without needing to be physically present.

Choosing the wrong WMS can break your operations

Some businesses have failed in implementing WMS—not because the technology didn’t work, but because the solution wasn’t the right fit. Some systems are too complex, overwhelming warehouse staff. Others require a complete overhaul of existing workflows, leading to operational disruption. Worse, some WMS platforms are too rigid to be customized to specific business needs.

That’s why choosing the right WMS is critical. Look for one that is easy to use, quick to implement, and flexible enough to fit your operations, not the other way around.

GITS WMS – The smart warehouse solution for logistics businesses

Recognizing the distinct operational challenges faced by logistics companies, GITS developed GITS WMS—a modern and flexible warehouse management system specifically tailored for the local market.

Unlike rigid off-the-shelf software, GITS WMS is designed to adapt—whether you run a small warehouse with a few hundred SKUs or a large distribution center with tens of thousands. It offers real-time inventory control, barcode scanning, role-based permissions, and seamless integration with ERP, TMS, or third-party shipping platforms.

In just a short time, your business can digitize its entire warehouse operation—without disrupting workflows, without investing in complex hardware, and with full support from GITS experts for training, implementation, and ongoing optimization.

Final thoughts

Digital transformation is no longer optional—it’s a matter of survival in the fiercely competitive logistics landscape. And your warehouse, the heart of your supply chain, is the ideal place to begin.

A smart WMS not only streamlines operations but also delivers real value through improved productivity, better service quality, and stronger profitability. Don’t wait for your warehouse to become a bottleneck. Take action today—and lead the way in modern logistics.