Overview

The construction industry is undergoing a significant digital transformation, with autonomous technologies reshaping how large-scale civil engineering projects are executed. One of our clients, a leading player in infrastructure development, approached GITS with an ambitious vision: to develop a fully automatic and autonomous driving construction system capable of handling complex embankment work.

The customer’s requirements centred on creating a comprehensive platform that could automate a series of construction tasks—including loading materials, transporting them onto dump trucks, levelling terrain, compacting soil, and shaping landscapes. The ultimate goal was to build an open, scalable construction system that would revolutionize how heavy machinery operates on large-scale civil engineering sites.

This case study explores how GITS successfully delivered an end-to-end autonomous construction system that exceeded client expectations while navigating significant technical and organizational challenges.

Key Features

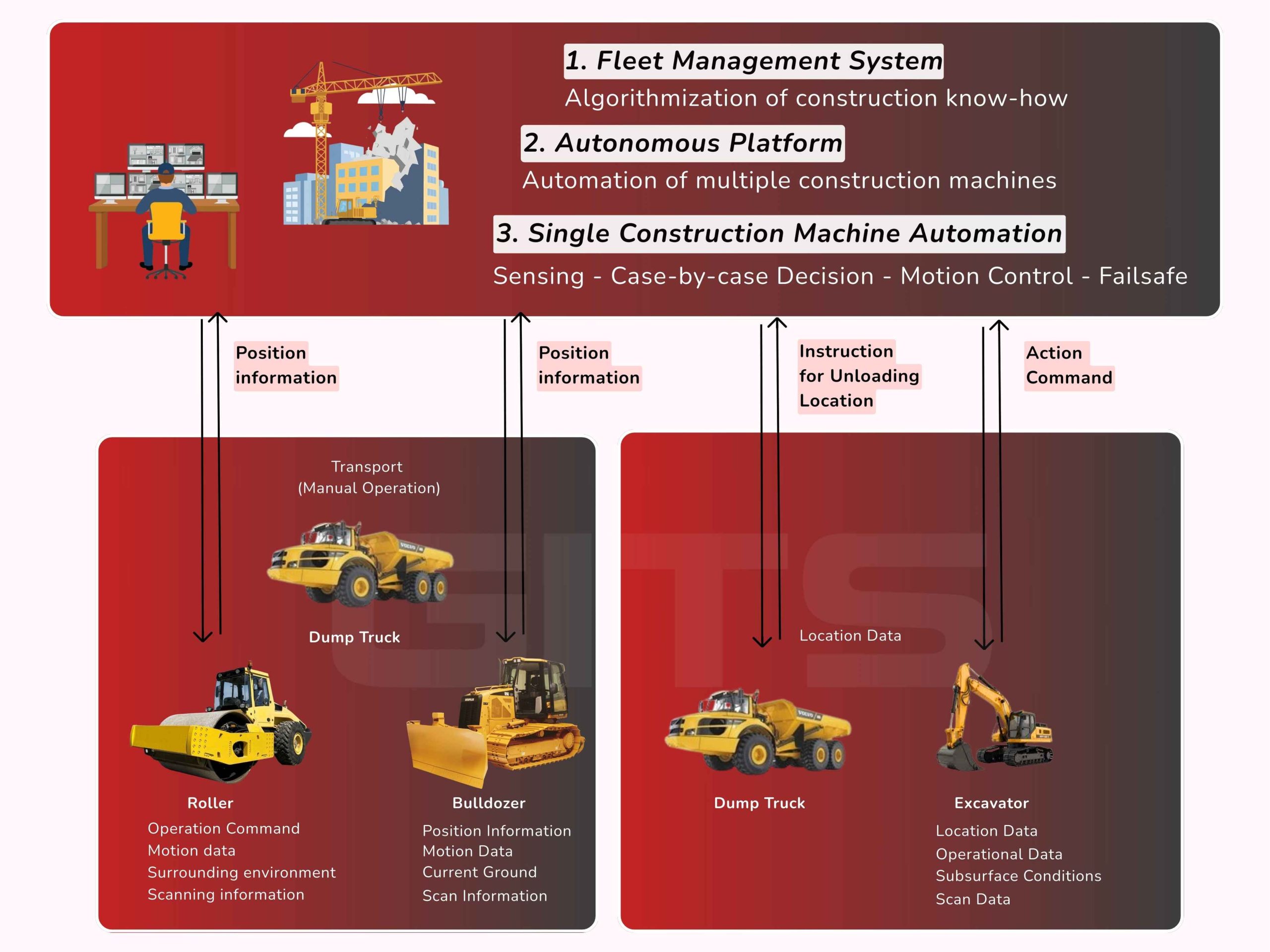

The autonomous driving construction system developed by GITS comprises two core components designed to work seamlessly together.

Fleet Management System

The fleet management module serves as the operational brain of the entire construction system. It enables real-time scheduling and monitoring of work areas, tracking the number of vehicles deployed each day. Project managers can leverage route planning and location tracking capabilities to optimise machinery movement across the site. Additionally, the system provides comprehensive driver management, work sequencing, capacity planning, and quality control—ensuring every aspect of the construction process remains transparent and measurable.

Autonomous Platform

At the heart of this construction system lies the autonomous platform, which powers automated heavy machinery with intelligent navigation capabilities. The platform manages multiple vehicles operating simultaneously within designated areas, coordinating their movements to prevent conflicts and maximize efficiency. A sophisticated simulation system issues operation commands to construction machinery based on predefined instructions, while 3D visualization maps allow stakeholders to monitor progress and preview finished shapes before physical work begins.

Challenges

Implementing this cutting-edge construction system presented several significant obstacles that required innovative problem-solving approaches.

First, our team faced the challenge of limited experience with rapid POC development using the Autoware platform—a critical foundation for autonomous vehicle operations. Building expertise in this specialised technology within tight timelines demanded intensive knowledge acquisition and hands-on experimentation.

Second, the customer’s specifications remained fluid throughout the implementation phase. Requirements evolved continuously as stakeholders refined their vision for the construction system, creating uncertainty that traditional waterfall methodologies could not accommodate.

Third, the client lacked internal developer resources with expertise in AI and machine learning technologies. This knowledge gap meant GITS needed to assume full technical ownership while ensuring knowledge transfer for long-term sustainability.

Finally, developing a simulation application capable of accurately mapping real-world vehicle behaviour proved exceptionally complex. The construction system required precise digital twins that could replicate the physical movements of machinery under varying site conditions.

Solutions Implemented

GITS addressed these challenges through strategic resource allocation and adaptive project management methodologies.

We assigned senior engineers with proven experience in AI and autonomous systems to lead the development effort. These high-level technical specialists brought deep expertise in machine learning algorithms, computer vision, and robotics—capabilities essential for building a sophisticated construction system.

Recognising the dynamic nature of client requirements, we established a highly flexible development team structured around agile principles. This approach allowed us to embrace changing specifications as opportunities for improvement rather than obstacles to progress.

Most importantly, our team proactively identified potential technical issues before they materialized. By anticipating challenges and proposing specifications to the customer in advance, we transformed ambiguity into clarity—ensuring the final construction system aligned perfectly with operational needs.

Conclusion

This project demonstrates GITS’s capability to deliver complex autonomous construction system solutions that address real-world industry challenges. By combining technical excellence with adaptive project management, we helped our client achieve their smart construction transformation goals—setting new standards for efficiency, safety, and innovation in civil engineering operations. Contact us now to get free demo for your construction system!