About customer

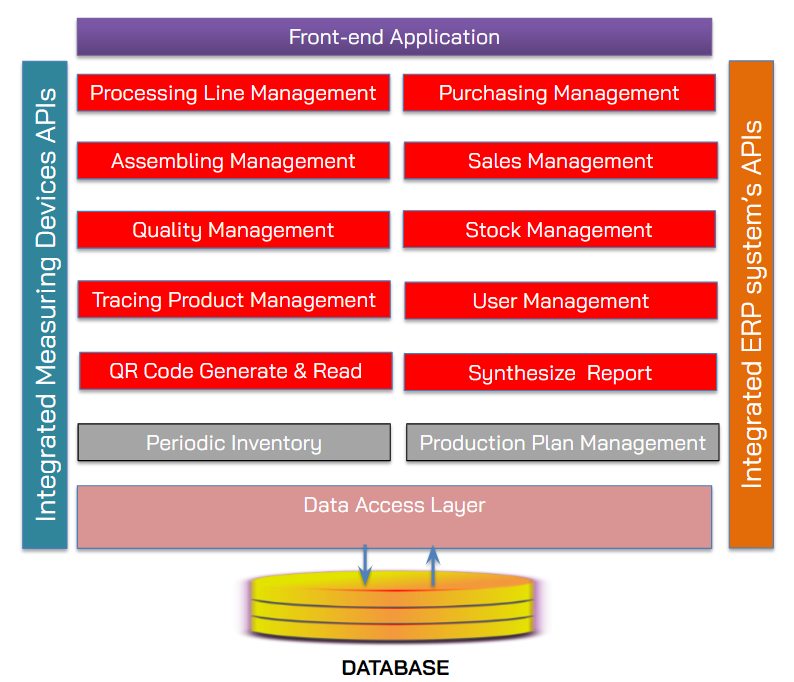

Our client is one subsidiary of a Japanese Heavy Industry Group, strategically located in the growth region of South East Asia; Hanoi, Vietnam. They want to build a system to manage the production process including from procurement, warehousing, processing, assembly and quality management.

At the same time, customers want to develop the product traceability function throughout the stages. The system also needs to integrate with external systems such as: PLC, ERP of the parent company, etc.

Challenges

- Management by unproductive manual processes (e.g. MS Excel), resulting in discontinuous information flow between production stages.

- No description documents available on the current operation system and software, requiring investigation and assessment before deploying a new one.

GITS’s Solutions

We suggest customer divide to 2 phase:

- Business Analyze & Specification Definition

In this phase, our BA investigate all of production working flow and define which be processed by software and which be processed by manual or existing tools/systems. In the end of this phase, our BA make software specification and system architecture for next step. - Development

Base on output of 1st step, our team develop system, deployment and support go-live together with customer IT department.

GITS suggest solution integrating with Barcode/QR Code Devices APIs to get data for traceability functions. For PLC/ERP integration, we do co-work with customer IT and others vendor to define I/Fs.

Project Info & Technologies

- Team size: 15 member/month x 6 months.

- Technologies: Java Spring Boot, React JS.